Case Study

Sustainable Solutions in Action with Bushmills Irish Whiskey

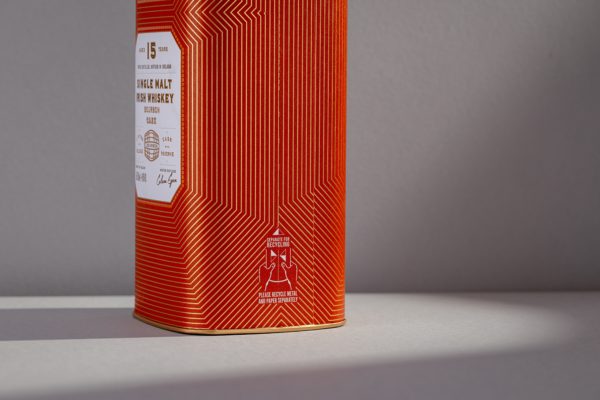

In 2021 one of our long-standing Tubes customers, Bushmills Irish Whiskey, was challenged on the recyclability of its products by a major UK supermarket.

Challenge

The team approached us for assistance and we embarked on a development process before arriving at a solution – a subtle perforation on the tube to allow the cardboard body and metal base of the product to be separated from each other and recycled.

Process

A collaborative process between the customer team and McLaren Packaging was undertaken, to identify a way to overcome the recyclability challenge.

Solution

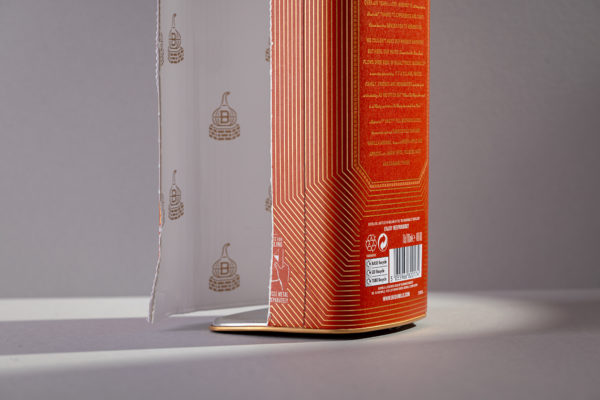

By employing the principles of sustainable design, we created a perforation on the tube to allow the carton board body and tin base to be separated from each other and recycled in the relevant recycling stream(s).

The patent pending design was approved for recyclability by On Pack Recycling Label (OPRL) in the UK.

Result

The customer was delighted with the separate for recycling solution and, importantly, it was approved by the supermarket! The more sustainable tube design has now been rolled out across the brands full range of tubes.

The new design has saved 10.5 metric tons of tin coated steel and 40 metric tons of paper going to landfill. We forecast that, by the end of 2025, this new design equates to the recovery of 74 metric tons of tin coated steel and 280 metric tons of high quality paper, essential for creating recycled products.

10 year old

10 year old

10 yo Vino Dulce Reserve

15yo World Wood Series GTR

15yo World Wood Series GTR

10 year old

Our whisky is packed in 100% recyclable packaging. Our tubes have the same distinctive look and feel, but it has been adapted to be easily recyclable at home.

Our tubes can be made with up to 60% recycled content giving additional life to recycled paper that no longer has the performance criteria for other applications.

Our tubes are manufactured within the UK minimising Co2e associated with transport.

The energy used to produce our tubes comes from renewable sources including one third through installed solar panels, at the manufacturers site, which produce green energy.

Our tubes comprise of a paper body and metal base and lid. The two materials have amongst the highest recycling rates of any readily used to make packaging. They require no specialist processing to recycle and are widely recovered globally.

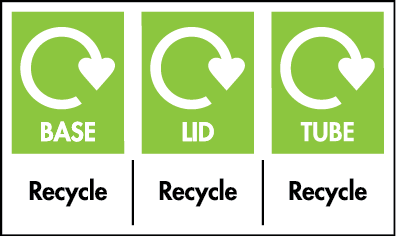

When disposing of the packaging, please follow the "on-pack recycling label" (OPRL) guidance below. The OPRL scheme aims to deliver simple and clear advice to consumers on how they can reuse then recycle in their local area.

For UK use only. Please check your local market recycling standards for more information.

Learn about our tube separation feature - the recycling solution on our round and shaped tubes.

At McLaren Packaging, we employ the principles of sustainable design to improve the recyclability of our products.

We have created a separate for recycling solution on our round and shaped tubes to allow the carton board body and tin base to be easily separated from each other and recycled in the relevant waste recovery streams.

Our innovative separate for recycling design has now been adopted by 70% of our shaped tube customers and our aim is to reach 100% by the end of 2024.

Collectively we are creating eye catching, eco-conscious packaging designs that are Sustainable. For Life.